Agile product development may have originated in the software world, accelerating the speed at which digital products are developed, tested, launched, and improved, but this doesn't mean that Agile only works for software products. Many manufacturers have adopted agile methods or a hybrid approach for developing complex cyber-physical goods, with Tesla leading the way as an innovative and pioneering company.

Agile product development may have originated in the software world, accelerating the speed at which digital products are developed, tested, launched, and improved, but this doesn't mean that Agile only works for software products. Many manufacturers have adopted agile methods or a hybrid approach for developing complex cyber-physical goods, with Tesla leading the way as an innovative and pioneering company.

While some organizations shy away from Agile because they believe they are not equipped to follow in the footsteps of Tesla, it is feasible to adopt Agile principles in different ways. Manufacturers of all sizes can speed up the development of their products by adopting a culture of experimentation, prioritizing testing, and iterating for more frequent improvements.

The Basics of Agile Product Development for Manufacturers

The reality is that manufacturing physical products involves longer lead times, less flexible production capacities, and complex supply chains. These factors make it harder to implement certain Agile practices like rapid iterations and quick launches. However, with careful planning, adaptation, and a willingness to innovate, many companies can implement Agile principles or at least a hybrid approach.

With the help of Agile framework guidelines, such as SAFe, manufacturers can customize their processes to fit the specific needs and constraints of their production environment. Regardless of your current system, there are three best practices to follow to become more flexible, adaptive, and innovative.

Best Practice #1: Facilitate Transparency and Communication through Roadmaps

Communication is what connects your teams together. It’s also one of the more challenging aspects of large organizations and product development as a whole. Many teams are involved in product manufacturing, from research to planning to building and testing to interviewing the customer. And each team needs different information to contribute to the process.

Communication is what connects your teams together. It’s also one of the more challenging aspects of large organizations and product development as a whole. Many teams are involved in product manufacturing, from research to planning to building and testing to interviewing the customer. And each team needs different information to contribute to the process.

The challenge is this: with hundreds, even thousands of employees located in various geographic locations, how do the leaders of any organization maintain effective communication with their managers and their teams?

The answer is that with the right systems, tools, expectations, and work culture, all teams can stay connected through transparent communication channels. Having a single source of truth—your product roadmaps—for all product-related data keeps leaders on the same page at all times. Transparency also makes it easier to align with company goals, analyze results, and pivot with less resistance.

Creating a Central Source of Information

Agile product planning requires strong communication channels and a central source of information. For example, when it comes to overseeing the product portfolio, using product roadmap management tools that connect all stakeholders and display updated information makes it far easier to discuss what action needs to be taken on any given product at any time.

Agile product planning requires strong communication channels and a central source of information. For example, when it comes to overseeing the product portfolio, using product roadmap management tools that connect all stakeholders and display updated information makes it far easier to discuss what action needs to be taken on any given product at any time.

Having a central source of information about all product lines also makes decisions easier, whether it's a product manager planning a review of a product or an executive evaluating progress on company goals.

Best Practice #2: Encourage Cross-Functional Team Collaboration

The saying goes that two minds are better than one. With big organizations, this only rings true if the right minds are in the right room at the same time. Encouraging cross-functional teams to work together often leads to building better products because ground-breaking innovation doesn't happen in a silo.

Cross-functional collaborations bring together diverse perspectives, expertise, and skills from different departments. This dynamic fosters creativity, problem-solving, and a deeper understanding of the customer's needs and wants. Ultimately, a collaborative approach leads to higher-quality products, reduced time-to-market, and increased competitive advantage in today's dynamic business environment.

Collaborative Problem-Solving

Bringing together individuals from different departments creates a room with diverse perspectives and expertise. These teams are better equipped to consider various factors, hold in-depth discussions, and find potential solutions more quickly. Collaborative meetings should be considered during product planning sessions, product review meetings, and prioritization discussions.

Improved Product Quality

Having multiple stakeholders in a room together creates space to focus on product quality and meeting customer requirements. By integrating input from various stakeholders early in the product development lifecycle, teams can identify potential quality issues, address them proactively, and deliver products that meet or exceed customer expectations.

Shared Access Roadmaps

Effective product roadmaps are those that can be shared with a diverse team. Seeing the product timeline on the roadmap, the supporting products in the brand, aligned with future initiatives and forecasts, ensures all stakeholders know what is happening. When everyone is informed, more time can be spent encouraging the exchange of relevant ideas, sparking creativity and innovation. Using product roadmap management software enables teams to share information quickly and accurately.

Faster Decision-Making

Cross-functional teams also empower each other to make decisions collectively rather than relying solely on hierarchical structures. When one team embraces agility, they can inspire other teams to follow suit. When cross-collaborative teams implement a streamlined decision-making process, they are better able to respond quickly to challenges, adapt to changing market demands, and accelerate product development timelines.

Best Practice #3: Promote Flexibility and Adaptability

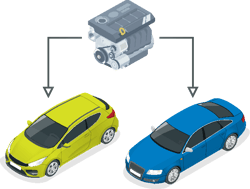

Agile implies flexibility and adaptability. The manufacturing of physical goods will never match the speed of software development’s adaptability, but it can make improvements that make sense for the industry. Platforming, along with continuous testing and iterating, is one strategy that creates more room for flexibility and changes to meet the market demands. However, aside from system changes, one of the most impactful ways to encourage flexibility is for leadership to set an example.

Agile implies flexibility and adaptability. The manufacturing of physical goods will never match the speed of software development’s adaptability, but it can make improvements that make sense for the industry. Platforming, along with continuous testing and iterating, is one strategy that creates more room for flexibility and changes to meet the market demands. However, aside from system changes, one of the most impactful ways to encourage flexibility is for leadership to set an example.

Adopting an Agile Mindset

Switching to Agile doesn’t happen overnight. Team members are more likely to adopt and follow Agile principles when their leaders and managers set a strong example. This requires leaders to adopt an Agile mindset before expecting their teams to buy in and see it through.

Embracing a Hybrid Approach

Large organizations that build complex products with cyber-physical components are successful when they embrace a hybrid approach rather than trying to force an Agile system on all their teams. The trick with a hybrid approach is to ensure your management can navigate the differences between teams and keep everyone on track. This will require syncing the milestone cadences to ensure smooth schedules.

Apply Lean Manufacturing Principles

Embrace lean manufacturing principles to eliminate waste, streamline processes, and improve efficiency. Try encouraging continuous improvement initiatives such as Kaizen events, Gemba walks, and Value Stream Mapping to identify opportunities for optimization and adaptation. Following SAFe principles can help manufacturers adopt lean manufacturing principles.

Product Roadmap Management Software for Hybrid Development Teams

Promoting flexibility and adaptability in large manufacturing organizations requires a multifaceted approach that addresses various aspects of the organization's culture, processes, and structure. By implementing these strategies with help of an enterprise product roadmap management software, large manufacturing organizations can foster a culture of flexibility and adaptability that enables them to thrive in an increasingly dynamic and competitive market environment.

Book your free demo to see the capabilities and benefits of The Gocious Product Roadmap Management software.