Managing products at the module level presents a unique set of challenges that require careful navigation and strategic planning. One of the top challenges lies in coordinating the production of modules, ensuring they meet quality standards, pricing objectives, and delivery timelines.

Managing products at the module level presents a unique set of challenges that require careful navigation and strategic planning. One of the top challenges lies in coordinating the production of modules, ensuring they meet quality standards, pricing objectives, and delivery timelines.

Product managers must know where their product is on the development roadmap at all times. Managing modules presents unique challenges, depending on the complexity of the product and where each part is coming from. Other significant challenges include effective communication, negotiation, and contract management. Each piece is essential to ensure the product's reliability, consistency, and cost-effectiveness.

The following are some of the top challenges in product management at the module level and how to address them.

11 Challenges of Module Dependency Management in Complex Products

Companies with complex products need to have strong teams overseeing development and product planning. Underneath those teams are multiple other groups working on projects and modules. The main theme in the following challenges and suggested solutions is how to gain visibility of those other layers of the product.

Challenge #1: Complexity

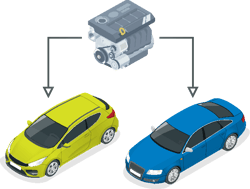

The greater the product's complexity, the more layers of modules are involved. This creates challenges in managing project timelines, tracking inventory, and ensuring the right pieces are in the right locations when needed.

The greater the product's complexity, the more layers of modules are involved. This creates challenges in managing project timelines, tracking inventory, and ensuring the right pieces are in the right locations when needed.

Solution:

The right tools and solutions can significantly improve the management of complex products, but they don’t work automatically. An organized system for module management, project coordination, and transparent communication is essential to using these tools effectively.

Having a high-level product portfolio roadmap management tool can help you oversee all the moving pieces while focusing on specifics as needed, which is essential for complex products.

Challenge #2: Supply Chain Management

Complex products require coordination with multiple suppliers to source parts for different modules, which brings another set of challenges. Working with external suppliers increases the risk of timeline adjustments, quality issues, sudden changes in pricing, and supply chain disruptions. How do you monitor the quality of each module and ensure they are on schedule and budget?

Complex products require coordination with multiple suppliers to source parts for different modules, which brings another set of challenges. Working with external suppliers increases the risk of timeline adjustments, quality issues, sudden changes in pricing, and supply chain disruptions. How do you monitor the quality of each module and ensure they are on schedule and budget?

Solution:

Product leaders must have a system in place to monitor the supply chain for changes in pricing, delays in delivery, and the corresponding dependencies in the roadmaps. Monitoring the interdependencies between the modules and the final products is vital to maintaining scheduled timelines.

Challenge #3: Quality Control

You want your products to be high-quality. That’s why you schedule quality assurance testing and evaluation into the product development schedule. The more complex the product is, the more modules are involved in building that product. How do you ensure all modules work well alone and once integrated with others?

You want your products to be high-quality. That’s why you schedule quality assurance testing and evaluation into the product development schedule. The more complex the product is, the more modules are involved in building that product. How do you ensure all modules work well alone and once integrated with others?

Solution:

Strict quality assurance processes are essential to ensure all parts meet the same standards; this applies to each module as well. Quality control measures must be implemented not only for the final assembled product but also for each individual module to prevent defects and maintain customer satisfaction.

Challenge #4: Inventory Management

Managing the inventory levels for modules requires careful planning and forecasting. Overstocking can tie up capital and warehouse space, while understocking can lead to production delays and lost sales opportunities.

Managing the inventory levels for modules requires careful planning and forecasting. Overstocking can tie up capital and warehouse space, while understocking can lead to production delays and lost sales opportunities.

Solution:

Inventory management requires a system of data reporting tools. To ensure that all inventory needs are heard and met, teams need shared access and cross-collaboration between stakeholders, just as they do with any other aspect of product management. Product roadmaps can also provide useful information, such as indicating which product lines need which resources and by what deadlines.

Challenge #5: Cost Management

Another factor to consider when managing products at the module level is procurement and cost management. While it may be tempting to limit the number of suppliers delivering important parts for your modules, not diversifying suppliers can lead to greater risk, especially if there is a shortage of materials. Managing costs becomes challenging as organizations strive to maintain competitive pricing while ensuring product quality.

Another factor to consider when managing products at the module level is procurement and cost management. While it may be tempting to limit the number of suppliers delivering important parts for your modules, not diversifying suppliers can lead to greater risk, especially if there is a shortage of materials. Managing costs becomes challenging as organizations strive to maintain competitive pricing while ensuring product quality.

Solution:

Routinely reviewing your modules is an effective way to find opportunities to improve the design and potentially reduce the cost of building it. Regular reviews can also highlight opportunities to work with different partners to source parts and materials for the module, which can also help reduce costs.

Challenge #6: Logistics and Transportation

Building modules is one challenge. Coordinating the transportation of modules from different suppliers to the manufacturing facility adds yet another layer of complexity to the equation. There are many possible causes of transportation delays or interruptions, including environmental factors, labor factors, geo-political factors, or basic human error. While it’s impossible to eliminate all risks, it is feasible to have plans and systems in place to react to surprise challenges.

Building modules is one challenge. Coordinating the transportation of modules from different suppliers to the manufacturing facility adds yet another layer of complexity to the equation. There are many possible causes of transportation delays or interruptions, including environmental factors, labor factors, geo-political factors, or basic human error. While it’s impossible to eliminate all risks, it is feasible to have plans and systems in place to react to surprise challenges.

Solution:

Knowing where modules are coming from and when helps keep product development on target. There are various ways to construct a transparent communication system. The product roadmap is one central location where alerts can be shared when modules are delayed for any reason. These alerts can trigger product meetings or put alternative plans into motion.

Challenge #7: Compatibility and Interoperability

Introducing a new module to an existing product or replacing one that is scheduled to be discontinued relies on compatibility and interoperability. It’s essential for all modules to work seamlessly together in the final product, or else compatibility issues can lead to product failures, performance issues, and customer dissatisfaction.

Introducing a new module to an existing product or replacing one that is scheduled to be discontinued relies on compatibility and interoperability. It’s essential for all modules to work seamlessly together in the final product, or else compatibility issues can lead to product failures, performance issues, and customer dissatisfaction.

Solution:

Ensuring that all modules are compatible is essential to product management. Your minimum viable product (MVP) phase needs to create an opportunity to test all proposed modules before investing in the full-scale product. Any new piece that is introduced to the product plan must also be tested to ensure the finished model works long before putting it in the hands of customers.

Challenge #8: Regulatory Compliance

It’s essential to meet your product performance standards and quality assurance measures. Meeting market regulations is also vital. Without meeting those external standards, your company runs the risk of having your product pulled from market lots or shelves. The modules that make up your product play a crucial part in ensuring the final product complies with the regulatory standards and certifications for each market.

It’s essential to meet your product performance standards and quality assurance measures. Meeting market regulations is also vital. Without meeting those external standards, your company runs the risk of having your product pulled from market lots or shelves. The modules that make up your product play a crucial part in ensuring the final product complies with the regulatory standards and certifications for each market.

Solution:

Keeping your teams aware of the necessary regulations is the first step to ensuring your products meet them. It's also useful to source parts from companies that also meet those standards, where applicable. Managing compliance across a complex product requires thorough testing and documentation to prove it.

Challenge #9: Risk Management

Highly complex products, such as cyber-physical products, naturally create bigger risks. There are more layers at play, a greater range of supplies and resources in use, and more stakeholders influencing the outcome. Each module of the product is subject to risks we’ve already covered in this article, such as resource availability, labor disputes, financial instability, or external factors, such as geopolitics or environment.

Highly complex products, such as cyber-physical products, naturally create bigger risks. There are more layers at play, a greater range of supplies and resources in use, and more stakeholders influencing the outcome. Each module of the product is subject to risks we’ve already covered in this article, such as resource availability, labor disputes, financial instability, or external factors, such as geopolitics or environment.

Solution:

Part of the product manufacturing process is developing risk mitigation strategies to minimize the impact of potential disruptions. While not every risk can be planned for or mitigated, the better prepared your company is for the unexpected, the better your reaction times will be and your solutions.

Challenge #10: Communication and Collaboration

Communication is key in every part of product development and management. Maintaining effective communication and collaboration among the various stakeholders, including suppliers, manufacturers, and internal project teams, is essential for managing products down to the module level. But how do you keep everyone aligned and in the loop when products are complex, and teams are located in various places around the globe?

Communication is key in every part of product development and management. Maintaining effective communication and collaboration among the various stakeholders, including suppliers, manufacturers, and internal project teams, is essential for managing products down to the module level. But how do you keep everyone aligned and in the loop when products are complex, and teams are located in various places around the globe?

Solution:

Clear communication channels and collaboration tools help ensure that everyone involved is informed about the product requirements and any delays, changes, or challenges to the products. Companywide messaging tools are one way to deliver specific and urgent memos between departments. The product roadmaps themselves are also vital communication channels where all product-related announcements should be shared.

Challenge #11: Syncing Timelines and Cadences

Sub-teams or partners may operate on a completely different timeline or product development framework than your core product teams. This is especially important with complex products that combine hardware and software. If you have some module-level teams developing software in an Agile environment and other module-level hardware teams working in stage-gate, the product leaders must find a way to sync the cadences of the milestones to ensure each module is ready for the other at the important deadlines.

Sub-teams or partners may operate on a completely different timeline or product development framework than your core product teams. This is especially important with complex products that combine hardware and software. If you have some module-level teams developing software in an Agile environment and other module-level hardware teams working in stage-gate, the product leaders must find a way to sync the cadences of the milestones to ensure each module is ready for the other at the important deadlines.

Solution:

Product roadmap management software is the best place to plan timelines and sync cadences between departments or product partners. Plotting all major milestones allows product managers to communicate and work with different departments to ensure every piece is ready to go at the right time and that potential delays are spotted early. Dependency delays can result in wasted resources, time, and frustrate your stakeholders. Preplanning and syncing delivery times can help eliminate those complexities.

Module Management Solutions

Addressing these challenges requires a holistic approach that integrates supply chain management, quality control processes, inventory optimization techniques, and effective communication and collaboration strategies. By proactively managing these challenges, organizations can enhance their ability to efficiently produce high-quality products while maintaining competitiveness in the marketplace. Excellent communication, transparency in the roadmap, and innovative tools that connect teams through regularly shared updates can all help improve module management for products.

Leading Tools for Product Roadmap Management

Overall, successfully managing products at the module level necessitates adept coordination, robust supplier relationships, rigorous quality control, and strategic risk management to achieve operational efficiency and deliver value to customers. Gocious product roadmap management software is a robust product management tool that connects teams, streamlines communication, and improves transparency and alignment across product stakeholders. Schedule your free demo to see how Gocious software can work for your company.